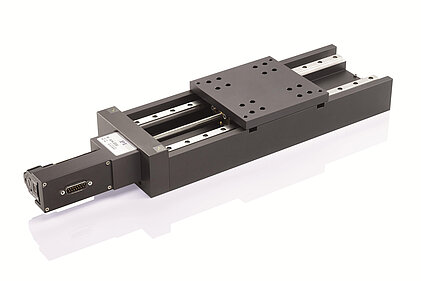

Stages with Stepper, DC & Brushless DC (BLDC) Motors

Industrial applications in the production process such as laser processing benefit from the precise positioning accuracy of motorized positioning stages. Their low profile makes the variable stage series suitable for universal use, ranging from testing systems to production lines in precision automation.

Standard stages are available in various load and precision classes for travel ranges up to 1 m. Miniature versions show footprints under 20 mm x 20 mm.