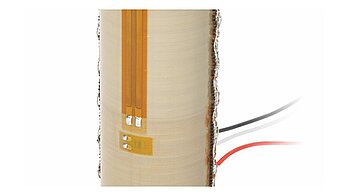

PI Ceramic integrates piezo ceramics into the customer’s product. This includes the electrical contacting of the elements according to customer requirements and the mounting of components provided by the customer, as well as the gluing or the casting of the piezo ceramics. PICMA® multilayer actuators may be integrated, for example, in the customers' own guiding mechanisms and mechanical levers.

PICMA® Piezo Linear Actuators

Multilayer Piezo Actuators with All-Ceramic Insulation

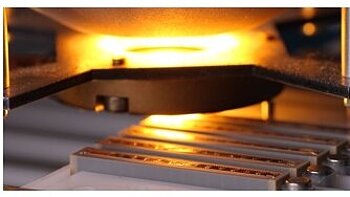

The PICMA® Stack piezo linear actuators from PI Ceramic feature linear displacements with low piezo voltages. Encapsulated versions for operation with splash water or oil are available.

The miniature actuators PICMA® Chip with a height of only 2 mm are also offered as round version with inner hole. These extremely compact piezo actuators feature maximum dynamics with high resonant frequencies. PICMA® Chip piezo actuators can be easily combined to stack actuators.

Customization

PICMA® multilayer piezo actuators are produced in different shapes. Depending on the application, they can also be assembled with adapted ceramic or metal end pieces, additional coating, temperature sensors, etc. On request, we will gladly offer you customized products.

- Precision mechanics and precision machining

- High-precision pumping and dosing

- UHV environments of up to 10-10 mbar

- Active vibration damping

- Pneumatic and hydraulic valves

Miniature Linear Stages

Miniature stages are essential in positioning tasks where available space is limited. Piezomotor solutions like Q-motion®, PIline® and PiezoWalk® allow for the most compact stages due to their direct drive principle.

PI’s stages with electromagnetic motors are present and proven in automation tasks worldwide. Ask for your customization!

Miniature Stages with PIMag® VC VoiceCoil and 3-Phase Linear Motors, Stepper, DC & Brushless DC Motors

Stages with Magnetic Direct-Drive Linear Motor

The friction-free magnetic direct drive principle allows for most dynamic stages. Compared with motor-spindle-based stages, they use fewer mechanical components which results in less friction and backlash and thus more precision.

PI’s PIglide stages combine the magnetic direct drive with highly precise preloaded air bearings for even better performance.

PIMag®

PI has many standard and customer-specific positioning solutions on offer that are equipped with magnetic direct drives; the company has also many years of experience in the design, construction, and manufacture of the necessary system components such as guides, sensors, control technology, and software. PI can also develop proprietary magnetic motors if positioning systems need to achieve specific performance characteristics that cannot be reached by using drive components currently available on the market, for example, to achieve a high force density or a compact design. These >> proprietary motors, developed in-house, are identified by the PIMag® brand name.

Linear Stages

PI offers a broad portfolio of motorized linear stages. The huge variety of applications also means a huge variety of technical possibilities for the linear axes. Travel ranges extend from a few millimeters to meters and for precision classes, from nanometers to micrometers: PI adapts the drive, guides or sensor technology to the application conditions.

There are vacuum versions for a large number of different models. Multi-axis combinations can be realized with the help of adapter brackets or be more compact with matching Z stages and rotation stages.

Motion controllers are available as benchtop devices, rack versions or compact OEM devices. The common factor for all of them is commanding via the General Command Set (GCS), which simplifies control and programming, and is independent of the drive type.

Multi-axis systems in multi-axis industrial applications with motion controllers from ACS are available. That ensures easy integration via Fieldbus interfaces for precision and motion-centric industrial applications.

Miniature Stages

Miniaturized stages and manipulators are essential in applications, where space is limited. This includes mobile applications for measuring and medical devices, in industrial microassembly or use for research, e.g. in UHV and non-magnetic environments.

Proprietary piezo motor technology allows for specific integrated solutions. High resolution even below nanometer can be achieved with all piezomotor solutions as the accuracy is only limited by the integrated sensor. They are self-locking with no energy consumption at rest and therefore ideal for set-and-forget applications. Drivers and motion controllers are available from rack models to the OEM module to the „intelligence on the chip“ to integrate.

For other uses, stepper, DC or VoiceCoil servo motors are available. Contact us for consultation on the best choice of drive and customization!

Rotation Stages

Requirements for rotary motion show a very broad range of different sizes, load capacity, and positioning accuracy. PI offers stages with all kinds of motorization and guiding options: air-bearing, torque motor driven, motorized worm-gear coupled, tiny piezomotor stages and specialized goniometer stages with orthogonal tip-tilt mounting option. All of them can be mounted to multi-axis combinations with corresponding linear, vertical and XY stages.

Air Bearings & Stages

Air bearing stages are used where vibration-free motion is required, velocity needs to be highly constant, and optimum angular repeatability is requested.

Air bearings avoid friction, wear, and backlash effects. PIglide linear, rotary and spherical bearings are precision components that can be integrated and motorized for applications in OEM, industrial, and research markets.

Nanopositioning Piezo Flexure Stages

PI's piezo flexure stages combine sub-nanometer resolution and guiding precision with minimum crosstalk. This makes them particularly suitable for applications in metrology, for super resolution microscopy, for interferometry or in inspection systems for semiconductor chip production. Piezo flexure stages are available for millisecond-settling precision positioning and dynamic scanning with up to several 100 Hertz in up to 6 degrees of freedom.

The unique combination of proprietary sensor design, frictionless flexure guides and long-life PICMA® piezo actuators makes for excellent and robust mechanics. Piezo motion controllers support positioning and scanning performance optimization, and are easily integrated over digital or analog interfaces and comfortable programming.

XY Stages

Stability, precision and dynamics are crucial in the application fields of PI’s XY stages. They are the basis of high throughput rates and reliable operation.

PI makes use of own developments in the fields of PIMag® magnetic linear motors and PIglide air bearings. Industrial production and quality control benefit from PI’s high-load XY stages and planar scanners.

For microscopy applications e.g. in the field of topology measurement, fast, repeatable scanning is combined with best velocity constancy by PIline® driven sample stages. Their low profile is outstanding in this field. Combination with piezo flexure sample stages makes them very versatile.

Products

PI Is a Worldwide Leading Supplier of Solutions in the Fields of Motion and Positioning

PI does not only develop and produce a broad range of positioning stages and actuators for linear, rotary and vertical motion or combinations of different axes. PI also adapts those solutions to customer-specific applications or supplies finished subsystems for motion and positioning.

The control is an important system component and is also supplied by PI. This not only provides sophisticated control concepts but also the hardware and software interfaces for the application environment.

Whether a standard product or a completely new development, whether OEM drive or an integrated system, the objective is always to provide the optimum solution for every possible application.

Piezoelectric Transducers & Actuators

Piezoelectric ultrasonic transducers are available in a wide range of shapes like disks, plates or tubes, and different performance levels. They can be adapted to application requirements by using different piezoceramic materials, electrodes, and assembling technology. They are present wherever ultrasound is needed, like in flow metering, structural monitoring, and many medical applications.

Piezo actuators are available as stacked and multilayer versions, in different force classes and for displacements up to some hundred micrometers, while piezo bending actuators achieve up to millimeters. Their basic features like millisecond response time and high dynamics combined with virtually unlimited resolution make them indispensable in applications from industrial production or dispensing to ultra-precision positioning.

Product Finder

What Is Your Simplest Way to Find a Suitable Positioning Solution?

Select the >> product type specified by the axes of motion required. Or use the >> selection according to application to set the criteria that are relevant for your special field of use.

Selection of more criteria expands or shortens the list of results. Select more than one filter at a time, for example, to find positioning stages designed for higher load capacity, too