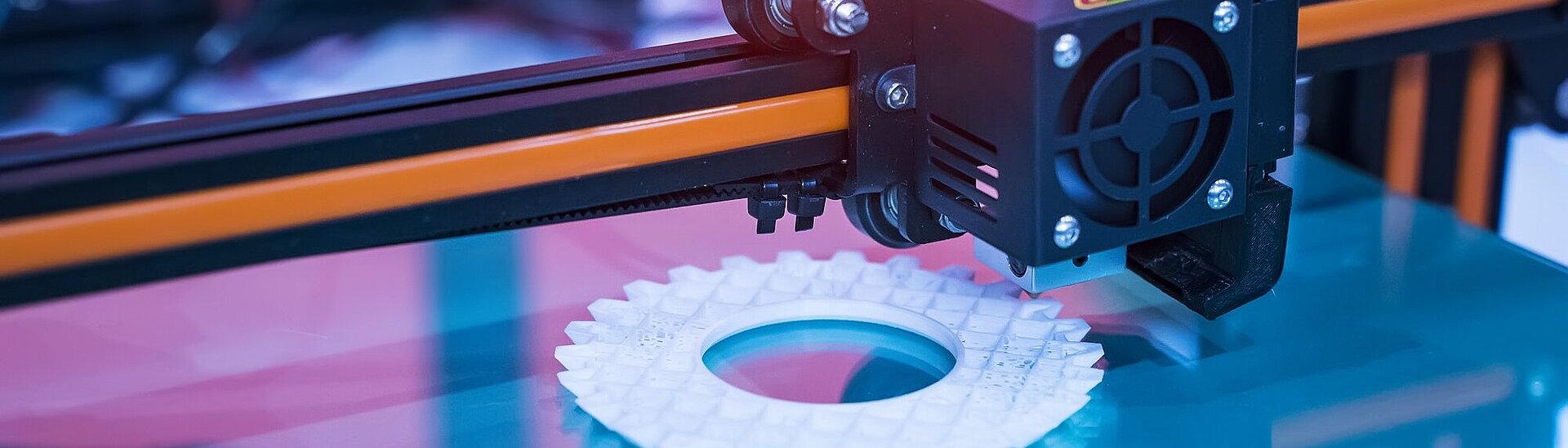

Manufacturing Prototypes and Customized Products Fast, Using Piezo Actuators for Continuous Shock-Free Material Transmission During Printing

Additive manufacturing with 3D printing methods opens up completely new possibilities for manufacturing complex components: Individualized prototypes or customized products can be very quickly produced on the basis of CAD data. 3D printing uses different printing media, e.g. polymers, varnishes, wax, or composite material filled with particles. There are virtually no restrictions to this technology. The most complex geometrical shapes are produced this way, and can even be printed with changing materials and material properties. The piezo actuators used in this process work with the fastest response times and above all with high force. This is how even highly viscous materials can be processed with 3D printheads and jets.

In these applications, piezo actuators provide a continuous and smooth material transmission from the printhead to the printing surface or the 3D component, which is created layer after layer. They are completely wear and maintenance free since they only use the friction-free piezoelectric solid-state effect. As these components do not need any power when at rest, they also score points in terms of their energy consumption.