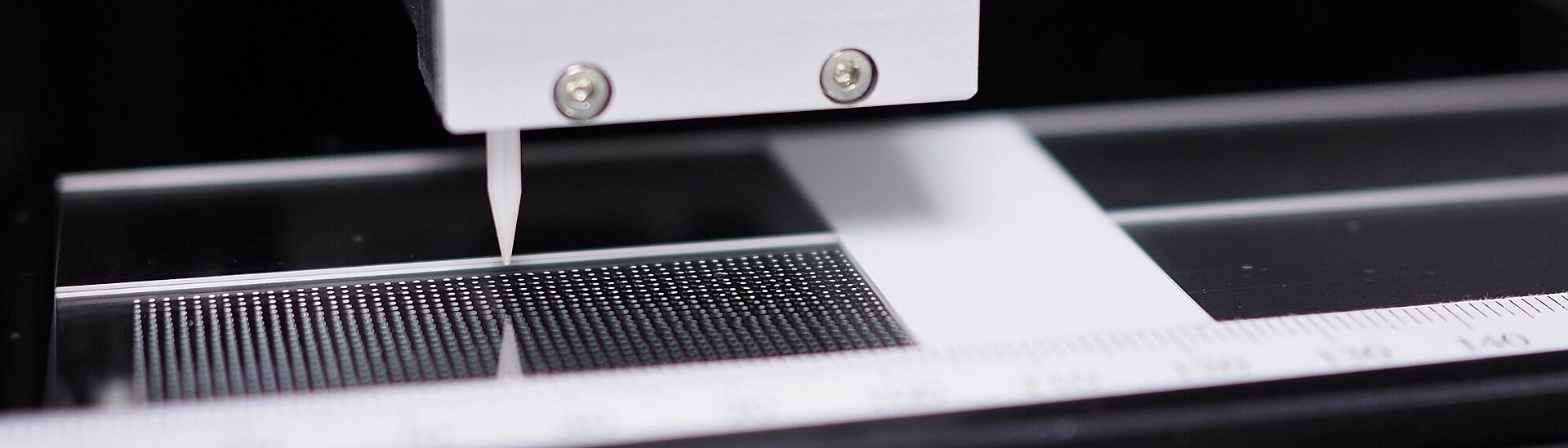

Printing Contacts in No Time with the Highest Precision Using the Advantages of Piezoelectric Actuators

High-precision dispensing is used in automated industrial production lines, for example, in the manufacturing of electronic components by printing contacts on circuit boards, microchips, or adhesive dots. For this purpose, highly viscous materials such as adhesives or soldering pastes are dosed ultrafast as finest droplets. The piezo actuators used have extremely fast response times in the microseconds range and frequencies up to a few kilohertz. In conjunction with a displacement in the micrometer range, piezo technology makes high-dynamics manufacturing processes possible. The contactless dosing of materials with differing viscosity, in particular, opens up new possibilities for the automated assembly of components.

Highly Dynamic Precision Dosing with Piezo Technology

PICMA® Actuators for Industrial Dispensing

Piezo actuators are, for example, used in pipe jet dispensers: Here they are in direct contact with pipes that carry the fluids. The expansion of the actuator leads to an immediate pressure impulse on the pipe, resulting in a droplet being generated – without contact and with minimized satellite formation. Piezo actuators work only with the piezoelectric solid-state effect, i.e., they do not have parts that move relative to each other and are, therefore, completely wear and maintenance free. Since they do not need any power when at rest, piezo actuators can also score points in terms of energy consumption.