Realizing Customized Printing Processes with the Help of Piezo Technology

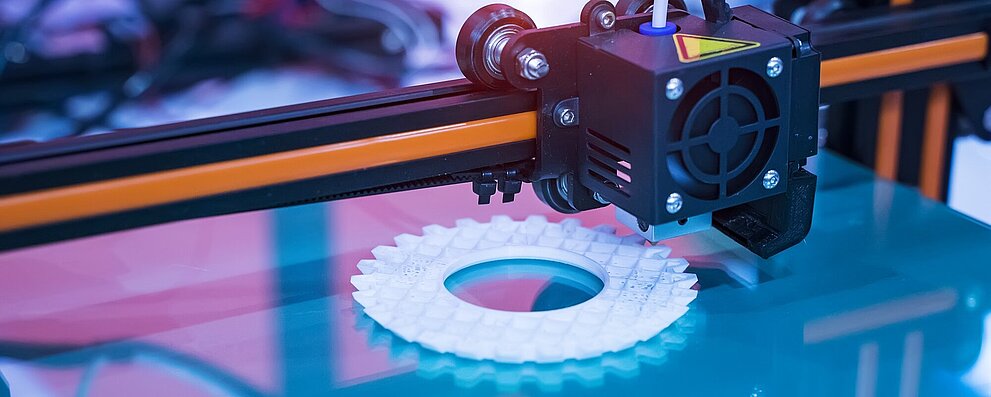

Printing technology has been an important sector in the industry for many years already – be it digital printing with its different procedures or, more recently, 3D printing. Particularly in the textile, food, or mechanical engineering industry, industrial printing plays an important role. The printing methods as well as their application areas are varied, but they have one thing in common: Their main objective is ultrafast and precise dispensing of liquid volumes down to the picoliter range.

With the jetting procedure, which is often the underlying procedure, liquids are dispensed without contact onto the printing material. This procedure makes use of the piezo effect. Piezo elements that are placed in the print head deform when an electric voltage is applied and generate a short force impulse on a nozzle. Therefore, a droplet is ejected by the print head and it is dispensed onto the paper. For different procedures in 3D printing, piezo actuators integrated into print heads can also ensure a continuous, precise, and fast dispensing of different media such as polymers, varnishes, or wax.

Piezo-driven dispensing systems can generate several thousand pico- to microliter droplets per second and with that reach a high throughput, which is becoming increasingly important in the industry. With its longstanding experience and the technical know-how in piezo technology, PI can develop and produce these piezo ceramic actuators – entirely according to the wishes of the customers and the respective industrial application.