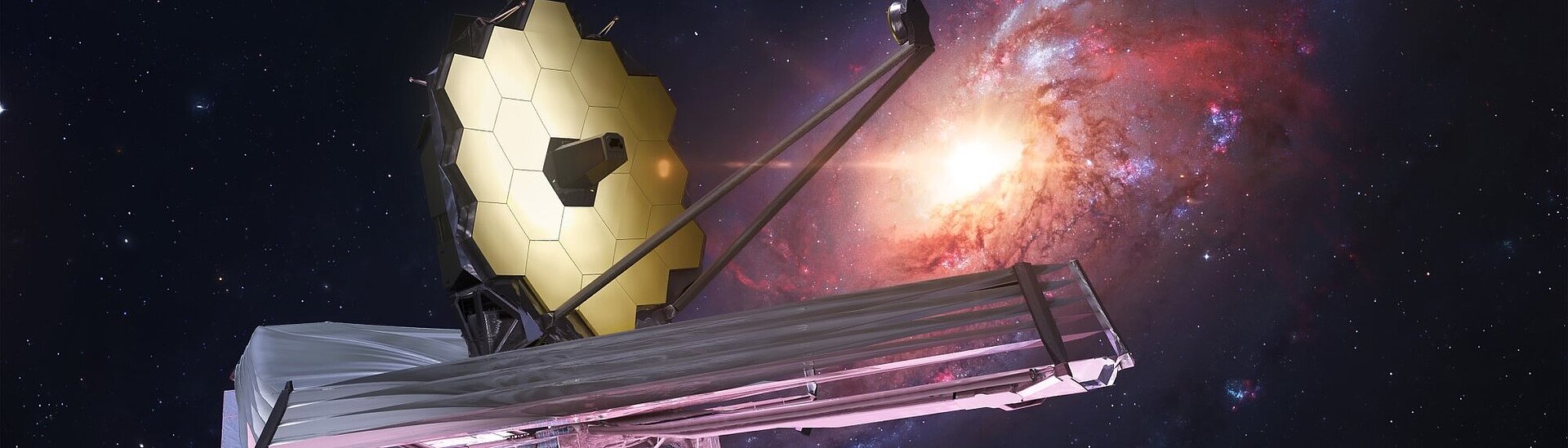

On December 25th, 2021, it was finally time for an Ariane 5 heavy launcher to propel the James Webb space telescope (JWST) into space. After thirty flight days, the Hubble space telescope's successor reached its destination at a so-called Lagrange point, 1.5 million kilometers away from Earth. From this point, together with Earth, the telescope will travel around the sun. Using mirrors and detectors, JWST can look back far into the past – right back to our universe‘s infancy. To do so, the telescope uses radiation from the red part of visible light (0.6 µm) up to mid-range infrared (28 µm). Its mission is to discover the beginnings of our universe, and, since July 11th, the JWST has been sending fascinating images from the depths of space. During assembly of JWST, which has a value of several billion dollars, PI technology came to the rescue several times in critical places.

Hexapod for Precise Positioning of the Main Mirror's Segments

JWST’s light, extendible main or primary mirror is divided into 18 hexagonal parts on a swiveling surface, with a diameter of more than 6.5 meters. In its extended operating state, this main mirror is almost as big as a tennis court. “In order for the combination of mirror segments to function as a single mirror they must be placed within a few millimeters of one another, to fraction-of-a-millimeter accuracy. A human operator cannot place the mirrors that accurately, so we developed a robotic system to do the assembly," said Eric Smith, Program Director of NASA's James Webb Space Telescope, at headquarters in Washington (source: >> NASA).

To precisely install the segments, the robotic arm with an application-specific PI hexapod at the end can move in six directions. This way, the individual mirror elements can be moved and positioned highly precisely using the telescope structure. Whilst one team of engineers maneuvers the robotic arm, another team takes measurements using lasers to ensure that each mirror segment is perfectly positioned, bolted and glued in place before mounting the next one.

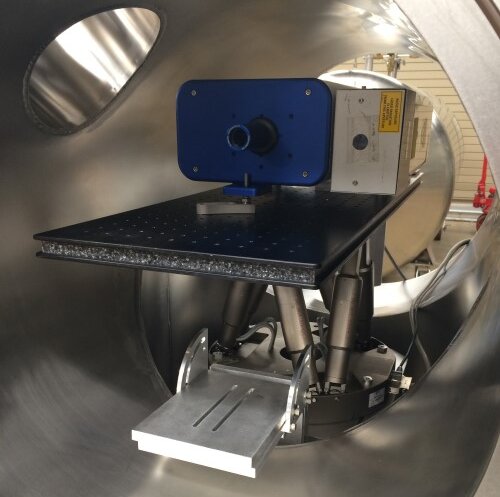

Mirror Measurement During Cooling

Whilst cooling down to the temperatures in space, the mirror segments and their supporting structure undergo high levels of thermic stress. Determining the resulting deformation in advance and considering this during the design process is extremely challenging. To observe the behavior of the segments during cooling, optical wave front tests and thermal structural deformation tests were conducted at the X-ray & Cryogenic Facility (XRCF) of the Marshall Space Flight Center. A customized variant of the H-850 hexapod was used for the complex test setup. To record mirror deformation whilst cooling down from room temperature, a specific interferometer was mounted onto the hexapod. The hexapod enables simple and, at the same time, high-precision positioning and alignment of the interferometer for each temperature target value.

Calibration of the NIRSpec Instrument

The NIRSpec (Near Infrared Spectrograph) Instrument integrated in JWST is a spectrograph for the wave length range from 0.6 to 5 µm. It can simultaneously record spectra of up to 100 objects. Whilst calibrating this object, the operating conditions in space were simulated, in particular, temperatures of 77 K (- 196.1 °C) and high vacuum conditions. Several PI linear axes were used for this purpose. By using a special type of aluminum called Dispal®, the axes could be designed to operate without errors under the climatic conditions specified.