The high-energy X-rays at beamlines provide numerous possibilities for materials research, such as checking welding seams or symptoms of fatigue of workpieces. This requires heavy loads to be positioned with an accuracy down to micrometers. Heavy-duty hexapods are perfect for these on-site measurements.

Strong Positioning System in Experimental Set-Up

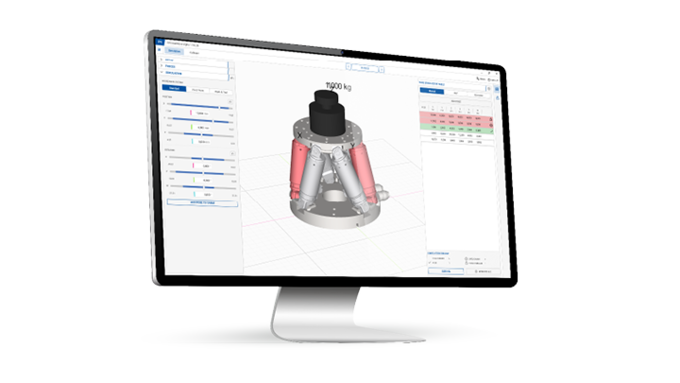

One example can be found in Hamburg at the PETRA III storage ring: The heavy-duty hexapod is used at a beamline for measuring material characteristics that occur during material modelling, for example. In consequence, these measurements give information on material aging and expectable useful life and lifetime. Effects down to the level of domain or crystal structures can be proven.

With its high load capacity of up to one ton, the hexapod positions the entire set-up over travel ranges of 400 mm with an ±1 µm accuracy. The set-up includes, for example, cylinder blocks, turbine parts, sintering furnaces, or cryogenic chambers, as well as welding apparatuses, or other machining tools.

Freely Definable Pivot Point

The hexapod controller communicates with the parent control of the measuring system. All desired motion commands are specified in Cartesian coordinates, while all transformations to the single drives are effected by the controller. Any desired point in space can be set as center of rotation using software commands. The movement of the hexapod platform can thus be precisely adapted to each individual task.