Higher Speed and Throughput for Microscale Fluid Handling

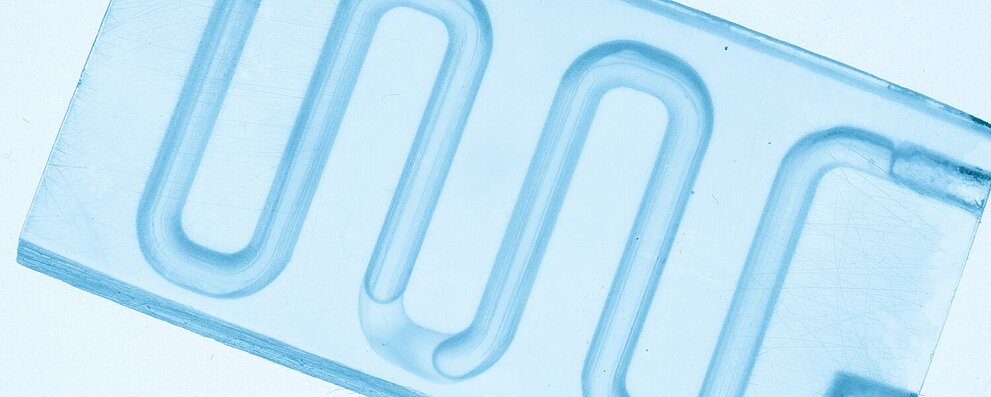

Enabling precise analysis, diagnosis, and therapeutic treatment, microfluidics brings benefits to fields such as chemistry, biotechnology, or medical technology. The integration of piezoceramic components revolutionizes the handling of liquid volumes down to the picoliter range. Due to their compact dimensions and high speed, as well as their low energy requirements and optional battery operation, piezo elements are suitable for applications in the smallest of installation spaces, such as in vitro diagnostics in point-of-care (POC) devices, various forms of drug delivery, and single-cell sorting.

Utilizing the piezoelectric effect, piezoceramics generate electrical charges under mechanical stress and deform under the influence of electricity.

As a result, piezoceramics can exert precise mechanical forces and achieve controlled deformations, including the generation of ultrasonic waves. Piezo elements can, for example, induce fluid movement in microchannels or dispense the smallest of volumes. As a result, they enable tasks such as mixing, printing, sorting, and dosing in microfluidic systems. Piezoceramics offer high sensitivity and precise control with fast response times, enabling a granularity that allows smaller sample volumes, improved analytical accuracy, and the ability of real-time monitoring.

Why Partner Up with PI Ceramic for Microfluidic Solutions?

PI Ceramic develops and manufactures customized piezoceramic materials and piezo elements for microfluidic applications in a wide variety of geometries, dimensions, designs, or higher refinements. Convince yourself of our comprehensive expertise in piezo technology, from research and development to production and further processing.

Customized products made of piezo materials developed in-house: We take care of all steps necessary for your application at our facilities, including manufacturing and assembling the piezo elements and ultrasonic transducers. With the entire value chain in our hand, PI Ceramic can guarantee consistent high quality across all process steps – and global supply fluctuations do not impact your order.

During the product development stage, PI supports you in finding the optimum design and the ideal specifications of piezo elements. Beyond that, we manufacture piezo components, subassemblies, and ultrasonic transducers. We keep the big picture in mind during all processes to ensure you get the ideal component for your application.

More than just piezo components or actuators: We offer value-added designs for our piezo elements. Whether you need soldering of stranded wires and flexible PCBs, gluing onto substrates, or the assembly of ultrasonic transducers with acoustic matching layers and housing: We deliver a ready-to-install, quality-tested product.

Special applications require special piezo elements. You are planning with the smallest installation spaces? PI Ceramic has the technical expertise to produce tiny piezo components for this purpose. Whether it is tubes with 0.4 mm diameter or 2 mm small spheres: We support you in miniaturizing your solution.