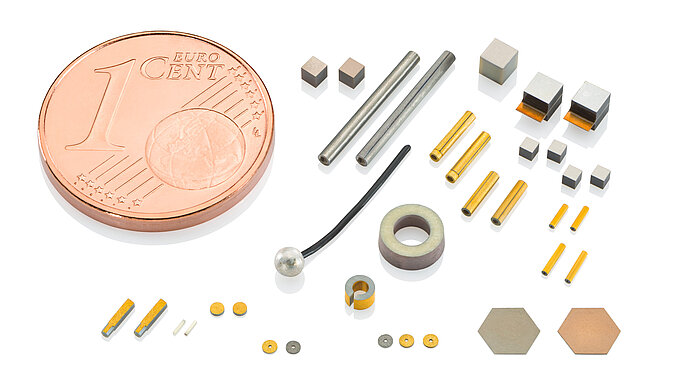

PI Ceramic has suitable tips and bases with standard dimensions in stock and mounts them prior to delivery. Possible tip designs are flat or spherical tips made e.g. of metal, ceramics, glass or sapphire. Application-specific end pieces can be manufactured on request.

Why Leading OEMs Trust PI

- Global OEM Supplier: 10M+ piezo components shipped annually

- ISO 9001 & ISO 13485 Certified: Medical, aerospace, and industrial compliance

- Custom and Standard Solutions: 500+ validated designs + full customization options

- Fast Prototyping: Tech Center enables samples in 4–8 weeks

- Volume Production Ready: Multilayer ceramics, components, and devices from one source

- 97% on-time delivery across Europe and North America with local UK-based experts

Certified Production and Quality You Can Rely On

Facilities:

10,000 m² manufacturing area in Thuringia, Germany

Local UK service, support, and inventory

Certifications:

ISO 9001 (Quality Management Systems)

ISO 13485 (Medical Devices)

EN 9100 (Aerospace Quality)

RoHS & REACH compliant manufacturing

Quality Control:

100% electrical, mechanical, and functional in-line testing

Traceability down to raw material batch

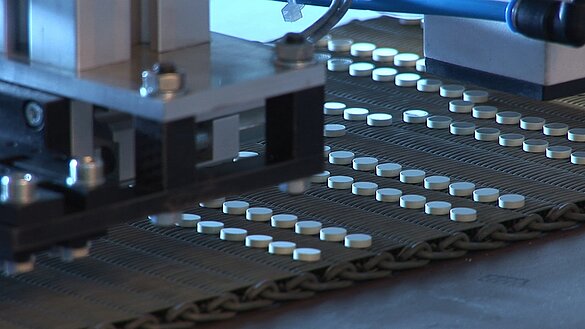

Automated optical inspection and precision measurement systems

Custom Piezo Solutions, Proven for High-Performance OEMs

The development and production of customized OEM adaptations for piezo ceramics is a complex process:

Long-term experience and the right machine tools are required to guarantee a prompt and reliable development of specific solutions. PI Ceramic is your reliable partner in piezo technology, capable of ensuring with specialists the entire production sequence in-house: From mixing to grinding, pressing to assembly. Apart from its technological know-how at the highest level, PI Ceramic always focusses on achieving the most economical solution.

High product quality, a reliable delivery, and a dependable operation for the intended application as well as a flexible scaling of the solutions are important criteria for the success of our customers. Our capabilities and facilities for current and future market needs include ISO 6 class clean rooms and modern production management to flexibly and quickly produce high volumes. The product division structure at PI Ceramic allows us to manufacture and qualify a wide variety of different products and ensure the specifications and quantities required by our partners.

Core Competences of PI Ceramic

- Customized solutions

- Almost 30 years of experience in piezo sensors and actuators

- Flexible assembling technology

- Complete solution:

Control electronics and mechanical integration - Short delivery times, fast delivery of prototypes

- High flexibility throughout the entire technological manufacturing process

- Production of single parts, minimum quantities and series

If you would like a quotation for piezo ceramic components please complete the form on the following page.

We will be in touch to discuss your requirements in more detail.

From the Prototype to the Series

Its installations for prototype construction, own development laboratories and test installations allow quick and flexible adjustment of the standard products to special fields

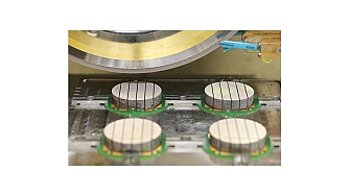

Our pressing and multilayer technology enables us to shape products with a short lead time. Individual production conditions ensure optimum material parameters.

This makes prototypes and small production batches of piezo components or piezo actuators available after only very short processing times. Series of medium and large quantities are manufactured and processed in automated lines. This also allows series of up to several 100,000 units per year to be produced economically.

All development, production and inspection processes take place in-house and are firmly established in the Integrated Management System (IMS). Especially OEM customers benefit decisively from the assured quality and on-time delivery performance.

Component or Integrated Assembly?

Whether you require a piezo component or an integrated assembly – PI Ceramic has the right solution ready for you.

Piezo components are manufactured from different piezo ceramic materials, each precisely tuned to the application. Further modifications of the elements, such as very fine holes, structured ceramic surfaces, and even complex, three-dimensional contours can be produced individually. Shaping takes place either in the "green state", i.e., before sintering, or the sintered piezo ceramics are processed by precision diamond saws or cutters, known from semiconductor technology.

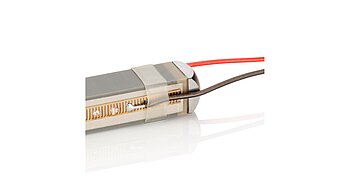

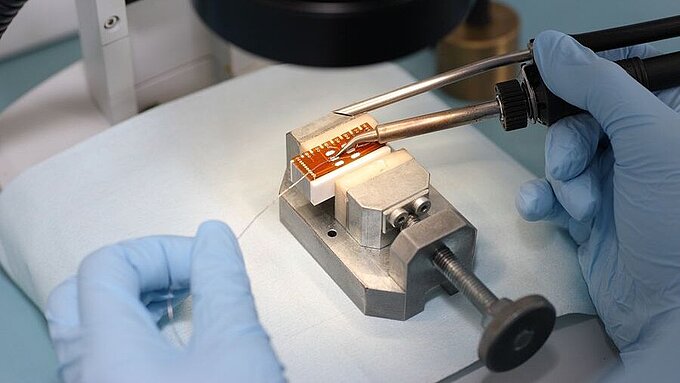

PI Ceramic also performs the integration of piezo elements into the customer product. This includes both the electrical contacting of the elements according to customer requirements and the mounting of components provided by the customer, as well as the gluing or the casting of the piezo ceramics. For the customer, this means an accelerated manufacturing process and shorter lead times.