56-Axes, 20 Tons, Nanometer Precision

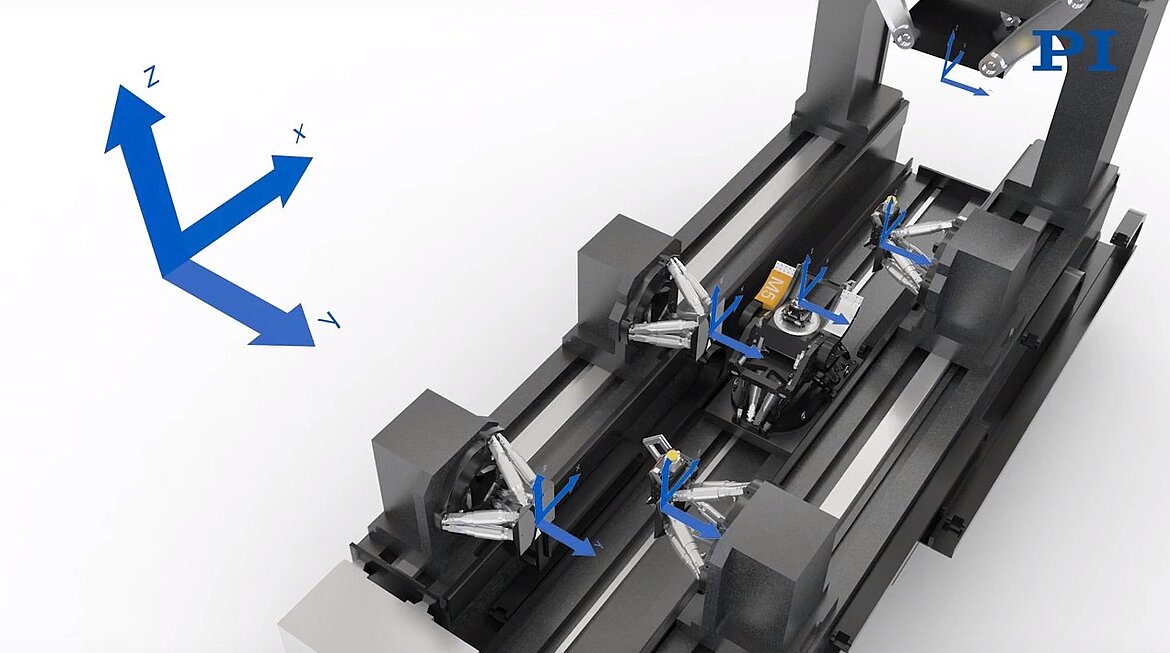

MiQA is a 20-ton, 56-axis motion system of extraordinary precision, designed for beam lines around synchrotrons and will be used for x-ray microscopy and quality assurance of x-ray optics such as lenses.

The system is equipped with 56 motors, 16 controllers, 7 air bearing granite sliders, and has an overall mass of more than 20,000 kilograms for moving and positioning small elements with the weight of only a few grams. In order to achieve nanometer level performance on a machine of this scale, the entire spectrum of PI’s precision technologies is put to use.

Integrated Spectrum of Precision Technologies – Standard & Custom

In addition to integrating and networking standard components, the challenging specifications required customized developments, such as an oval hexapod 6-axis parallel positioner, with 6 additional measuring legs for the highest levels of precision.

The detector stage is a custom kinematic motion system capable of moving payload of larger than 100kg in 3 DoF with less than 500nm resolution.

During experiments, the sample is fixed on top of the center stage. For sample characterization, it is essentially important to achieve the highest positioning stability in space.

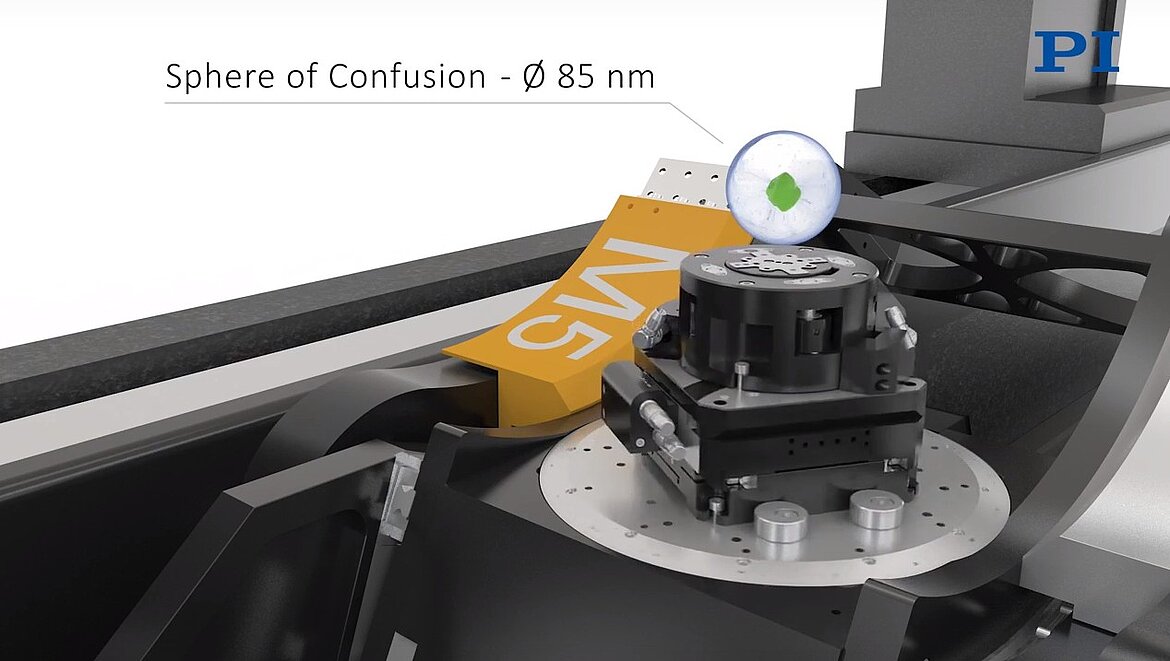

Tomography Mode: Sphere of Confusion as Small as 85 Nanometers

When operated in “Tomography Mode” the samples point of interest stays inside a spherical space with the diameter of 85 nanometers while the rotation stage turns over 360-degrees.

Ovali Hexapod

A special hexapod dubbed “Ovali” is the basic parallel kinematic machine of the sample stage. It is used to move the entire sample in and out of the x-ray beam to generate a reference image and afterwards to return to the previous position. This takes place with a positional repeatability of better than 200 nanometers, an extraordinary result considering its payload class. More: Novel Sample Stage Alignment Hexapod for X-ray Microscopy and Tomography

Software and Control Technology

The system architecture, consisting of 16 controllers, coordinates all operating status and all individual positions of all axes at any time. The system provides virtual coordinate system capabilities, configurable independently of the alignment of the station to the X-ray beam. Features like this make operation of complex technology easy.

Nanopositioning Stage for X-Ray Microscopy on a Smaller Scale

An application of a nanopositioning system in X-ray microscopy on a much smaller scale can be found in this article:

Scanning Transmission X-ray Microscopy with X-ray Fluorescence Detection at the XUV Beamline P04, PETRA III, DESY, by K. Andrianov et Al

Here, a compact P733 XYZ piezo flexure nanopositioning stage is employed to scan samples with a with a resolution of 0.1 nanometers. The specific design of the nanoscopy endstation allows to operate in STXM mode and full field mode to gain detailed insights into life science samples.