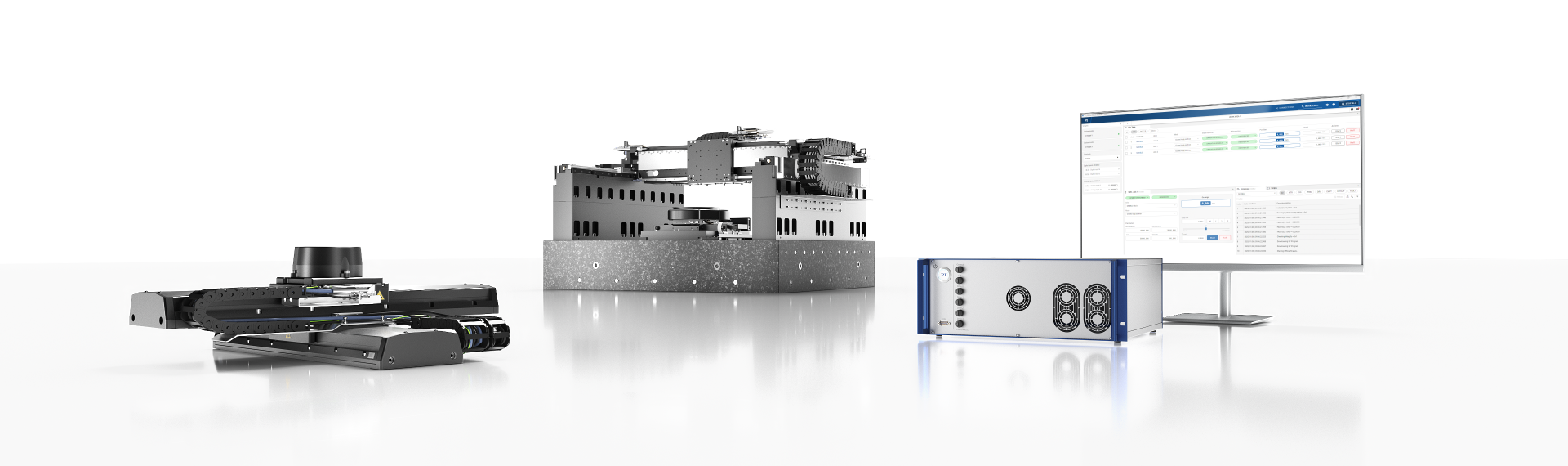

Turnkey Systems by PI: From Standard to Customized Multi-Axis Platforms

Finding the Best Motion Solution for You

Whether you need a quickly available, configure-ready system based on standard axes or an advanced multi-axis platform with extended customizable options, and everything in between: PI delivers the best fit for your requirements.

With a track record of excellence in integration, system-level mapping, and advanced control technologies, we’ll guide you from the initial idea to final commissioning. Throughout the process, our focus is on feasibility, efficiency, and the demands your specific environment poses. Simply tell us what you need, and we’ll make it work.

Our Comprehensive Service Portfolio

Benefit from Engineering Expertise, Add-Ons, and End-to-End Support

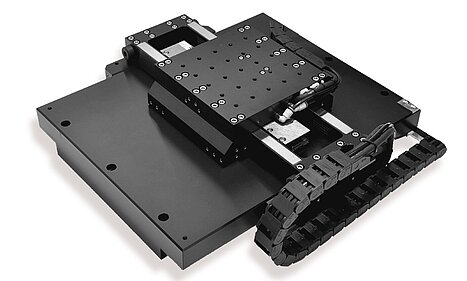

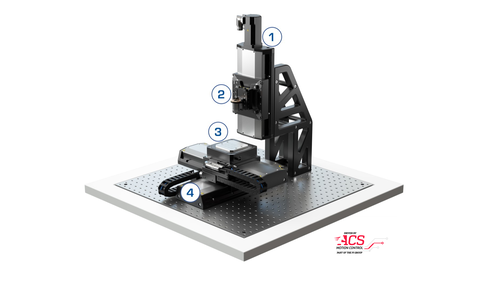

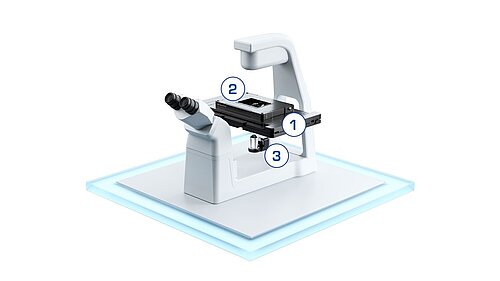

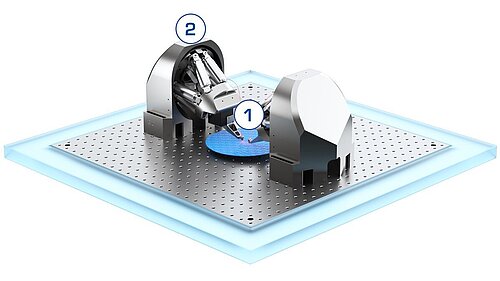

Turnkey System Setup

We deliver preconfigured, pretuned, and precalibrated systems using PLC and ACS motion controllers. These ready-to-run solutions use trusted PI hardware and control >> software, ensuring minimal setup effort and quick deployment: Plug it in and start working.

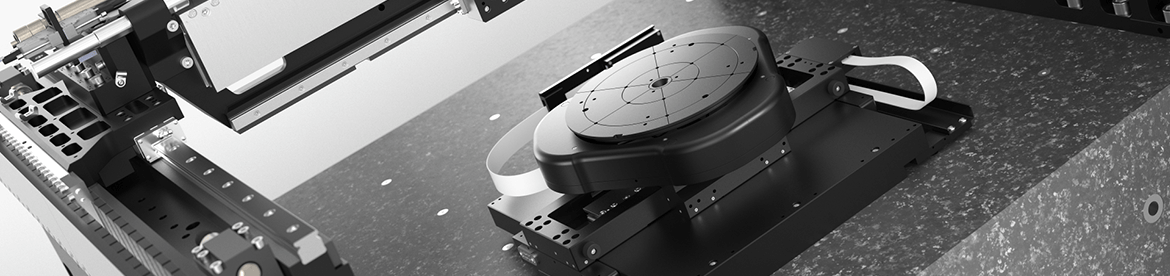

We validate motion quality and precision across one or more axes, optimizing your system’s alignment, path accuracy, and dynamics. 1D/2D mapping ensures repeatability and performance tailored to your application, supported by the same in-house tools used in PI production.

2D Calibration: For Maximum Efficiency and Precision

2D Calibration: For Maximum Efficiency and Precision

Our experts, Dr. Cliff Jolliffe and Gernot Hamann, demonstrated how Abbe and axis errors can be specifically compensated through 2D calibration – leading to greater accuracy, efficiency, and quality in industrial applications.

Comprehensive Service and Support

We support your system beyond delivery: from commissioning and troubleshooting to maintenance and lifecycle support, either remotely or on-site.

Application sizing and studies

We help you define the right mechanical setup based on loads, speed, accuracy, and duty cycles, while also analyzing behavior in real-world conditions. From initial sizing to reliability studies, including duty-cycle and dynamic performance validation, your system is engineered to perform.

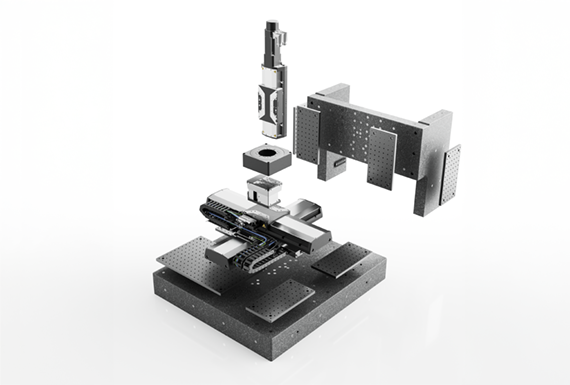

Easy Integration

Even with standard components, integration matters. We provide cable management, adapter plates, mounting interfaces, and documentation to create clean, installable setups, including safety consulting and interface definition.

PLC and software integration

We support integration into Beckhoff or ACS-based control environments—including basic I/O handling and sequencing support. This way, your motion system connects seamlessly to your automation environment.

Extend your system with plug-in >> accessories such as:

- Vision systems

- HMI devices (touchscreens, joysticks, >> controllers)

- Autofocus hardware

- Safety PLC and emergency stop integration

- Passive or active isolation

- Cooling units

- XL Scan or wafer chuck options

Special Environment Compatibilities

Our systems are available with cleanroom-ready components and >> vacuum-prepared options for demanding environments. This ensures precision is maintained even in highly sensitive applications.